HDPE Dam Liners Water Storage vs Concrete: Which is Better Option for Kenyan Farmers?

Water storage remains one of the most critical decisions facing Kenyan farmers and agribusinesses. With unpredictable rainfall patterns and increasing demand for irrigation, choosing the right water storage solution can determine your farm’s success or failure.

Most farmers consider two main options: HDPE dam liners and concrete water storage systems. Each offers distinct advantages, but understanding which fits your budget, land requirements, and farming goals makes all the difference.

This guide breaks down both solutions to help you make an informed decision. You’ll discover cost comparisons, durability factors, and practical applications that align with your specific farming needs.

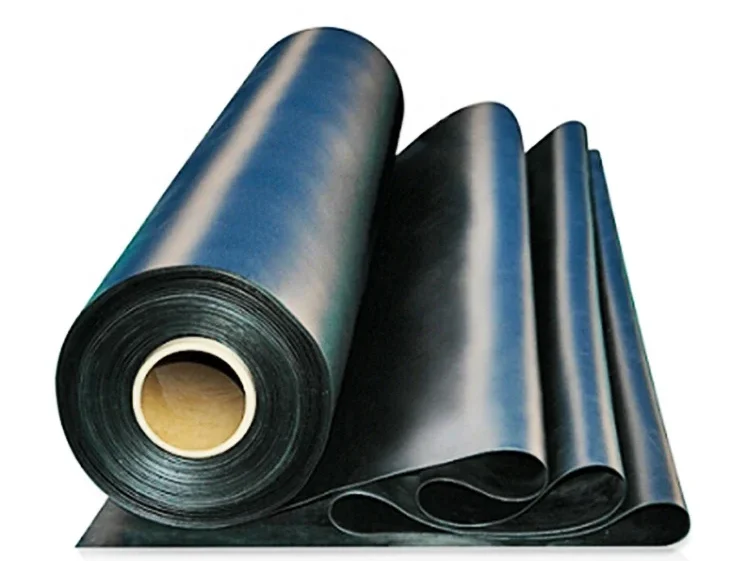

What is an HDPE Dam Liner?

High-Density Polyethylene (HDPE) dam liners are specialized plastic sheets designed to waterproof ponds, dams, and water storage areas. These flexible membranes prevent water seepage into surrounding soil, ensuring maximum water retention for your farming operations.

HDPE material offers exceptional durability and flexibility. The polyethylene composition resists UV radiation, chemical corrosion, and temperature fluctuations—essential qualities for Kenya’s diverse climate conditions. These liners can withstand both intense sun exposure and heavy rainfall without degrading.

Kenyan farmers typically choose from three thickness options: 0.5mm, 0.75mm, and 1mm dam liners. Each thickness serves different applications, from small-scale fish ponds to large irrigation reservoirs, providing flexibility for various farm sizes and water storage requirements.

What is Concrete Water Storage?

Concrete water storage involves constructing permanent structures using cement, sand, aggregate, and reinforcement materials. These systems include underground tanks, open reservoirs, raised water towers, and lined concrete dams.

Many farmers choose concrete for its perceived permanence and structural integrity. Concrete systems can support heavy water volumes and withstand mechanical stress from equipment and livestock access. The material also provides natural cooling, helping maintain water quality in hot climates.

Construction costs vary significantly based on design complexity, reinforcement requirements, and local labor rates. However, properly constructed concrete systems can serve farms for 15-30 years with appropriate maintenance and repairs.

HDPE Dam Liners vs Concrete: Key Differences

Cost Analysis

HDPE dam liners typically cost 30-50% less than equivalent concrete installations. Liner prices range from KSH 200-400 per square meter, while concrete construction averages KSH 15,000-25,000 per cubic meter of storage capacity.

Installation expenses also favor HDPE solutions. Liners require minimal excavation and can be installed by small teams within days. Concrete projects demand skilled labor, extensive foundation work, and curing time that extends project timelines significantly.

Durability Comparison

Quality HDPE liners last 7-15 years depending on thickness and environmental conditions. Concrete systems offer longer lifespans of 15-30 years but require regular maintenance to prevent cracks and leakage issues.

Repair complexity differs substantially between options. Liner punctures can be patched quickly using specialized adhesives and patch materials. Concrete repairs often require professional expertise, structural assessment, and expensive reconstruction work.

Installation Flexibility

Dam liners adapt to any pond shape or terrain contour, making them ideal for irregular landscapes common across Kenyan farmland. Installation teams can customize liner placement around rocks, slopes, and existing infrastructure.

Concrete systems require precise planning and cannot accommodate landscape changes after construction. Shape modifications demand additional construction phases, increasing both costs and project complexity significantly.

Dam Liner Thickness Guide for Kenyan Farmers

0.5mm Dam Liners

Best suited for small-scale applications including fish ponds, temporary water storage, and lightweight irrigation projects. These liners work well in areas with soft soil conditions and minimal mechanical stress. Cost-effective for farmers testing water storage solutions or operating on limited budgets.

0.75mm Dam Liners

The balanced choice for medium-sized farms and permanent irrigation systems. This thickness handles moderate soil movement, livestock access, and equipment operations while maintaining cost efficiency. Ideal for most commercial farming applications across Kenya.

1mm Dam Liners

Heavy-duty options designed for large dams, rocky soil conditions, and high-traffic areas. These liners withstand mechanical damage from farming equipment and provide maximum longevity for substantial water storage investments.

Choose thickness based on your soil type, expected usage intensity, and long-term storage goals. Rocky soils require thicker liners, while soft clay conditions may accommodate thinner options effectively.

HDPE Dam Liner Applications in Kenya

Irrigation water storage represents the primary use case, allowing farmers to collect rainwater or borehole water during wet seasons for dry-season crop production. This application directly supports food security and income diversification strategies.

Aquaculture projects benefit significantly from liner technology. Fish farming operations require reliable water containment without contamination from surrounding soil. HDPE liners create controlled environments that optimize fish health and growth rates.

Rainwater harvesting systems use liners to create collection reservoirs near homes and farming areas. These installations reduce dependence on distant water sources and provide backup supplies during drought periods.

Concrete Water Storage Applications

Domestic water tanks serve households and small institutions requiring reliable water storage. Underground concrete tanks protect water quality while maximizing available land for agricultural use.

Community water projects often utilize concrete systems for their perceived permanence and community ownership benefits. These installations support multiple households and can incorporate sophisticated distribution systems.

Industrial operations requiring large-volume storage with minimal maintenance prefer concrete solutions. The material’s strength supports heavy equipment access and withstands chemical exposure from fertilizers and pesticides.

Cost Analysis: HDPE vs Concrete in Kenya

HDPE dam liners range from KSH 200-400 per square meter depending on thickness. A 1000-square-meter pond (approximately 500,000-liter capacity) costs KSH 200,000-400,000 for liner materials plus installation expenses.

Concrete construction averages KSH 15,000-25,000 per cubic meter of storage capacity. The same 500,000-liter capacity requires approximately KSH 7,500,000-12,500,000 including materials, labor, and finishing work.

Short-term savings clearly favor HDPE solutions, while long-term considerations depend on replacement frequency and maintenance requirements. Most farmers find liner replacement costs remain lower than concrete maintenance over 20-year periods.

Maintenance and Lifespan Considerations

HDPE liners require periodic inspection for punctures, UV degradation, and seam separation. Maintenance involves cleaning debris, checking anchor points, and applying patches as needed. Replacement typically occurs after 7-15 years depending on usage intensity.

Concrete systems demand crack monitoring, waterproofing treatments, and structural repairs. Kenya’s climate cycles stress concrete through expansion and contraction, leading to maintenance requirements every 3-5 years.

Environmental factors affect both systems differently. Intense UV exposure degrades liner materials gradually, while temperature fluctuations cause concrete cracking and spalling over time.

Environmental Impact and Sustainability

HDPE materials offer complete recyclability at end-of-life, supporting circular economy principles. Used liners can be processed into new plastic products, reducing environmental waste from farming operations.

Concrete production generates significant carbon emissions through cement manufacturing. However, the material’s longevity and local sourcing availability may offset initial environmental costs over extended usage periods.

Sustainable farming practices benefit from both options when properly implemented. Water conservation achieved through either system supports soil health, reduces groundwater pressure, and enables climate-resilient agriculture.

Expert Recommendations for Kenyan Farmers

Small-scale farmers operating on limited budgets should prioritize HDPE dam liners. The lower initial investment, quick installation, and flexibility for farm expansion make liners ideal for testing and developing water storage strategies.

Medium to large-scale irrigation projects benefit from 0.75mm or 1mm liner thickness. These installations provide reliable water security while maintaining cost efficiency compared to concrete alternatives.

Urban institutions and households requiring permanent infrastructure may justify concrete investments. The material’s longevity and low maintenance requirements suit institutional applications with dedicated maintenance capabilities.

Community water projects require individual assessment based on available funding, local construction capabilities, and long-term management structures. Both options can succeed with appropriate planning and community commitment.

Frequently Asked Questions

How long does an HDPE dam liner last in Kenya?

Quality HDPE liners last 7-15 years depending on thickness and environmental conditions. Proper installation and maintenance extend lifespan significantly.

Can dam liners be repaired if punctured?

Yes, liner punctures can be patched using specialized adhesives and HDPE patch materials. Most repairs take less than one day to complete.

Is concrete water storage worth the cost?

Concrete systems justify costs for permanent installations requiring 20+ year lifespans with minimal replacement needs. However, most farming applications benefit more from liner flexibility and lower initial investment.

Which dam liner thickness should I use for irrigation water storage?

Choose 0.75mm liners for most irrigation applications. Use 1mm thickness for rocky soils or heavy equipment access, and 0.5mm for temporary or small-scale projects.

Where can I buy quality dam liners in Kenya?

Contact reputable agricultural suppliers who specialize in water storage solutions and can provide installation support and warranty coverage.

Choose the Right Water Storage Solution

Both HDPE dam liners and concrete systems serve important roles in Kenyan agriculture, but liners offer superior cost-effectiveness and versatility for most farming applications. The flexibility to customize installation, lower initial investment, and proven durability make HDPE liners the practical choice for farmers focused on maximizing returns.

Select your liner thickness based on farm size, soil conditions, and intended usage. Small operations succeed with 0.5mm options, while commercial farms benefit from 0.75mm or 1mm thickness for long-term reliability.

Ready to secure your farm’s water storage needs? Contact our team for high-quality 0.5mm, 0.75mm, and 1mm dam liners designed specifically for Kenyan farming conditions.